Welcome to the official website of Shandong Qigong Environmental Protection Technology Co., Ltd!

EPS Foam sandwich panel

Category:

EPS Foam sandwich panel

EPS Foam sandwich panel introduce:

Polystyrene foam board, also known as foam board and EPS board, is a white object made of expandable polystyrene beads containing volatile liquid foaming agent, which is heated and formed in the mold after being pre heated. It has the structural characteristics of micro closed holes. It is used in internal and external wall composite boards, with a thermal conductivity of about 0.035, a fire rating of B, and shrinks in case of fire; Mainly used for building walls, roof insulation, composite board insulation, cold storage, and other insulation, with a wide range of aesthetic and decorative purposes.

Product description:

| Product Name | EPS Foam Sandwich Panel |

| Material | Aluminum zinc plated steel plate+foam (EPS) sandwich+aluminumfoil insulation layer |

| Function | Wall decoration and insulation |

| Package | Carton (Hard kraft paper) packaging + Packaging belt |

| Color | Multiple colors or RAL color |

| Length | Within 12m as customer's request |

| Width | 383mm |

| Thickness | 30/50/75/100mm |

| Thickness of surface metal plate | 0.2-0.5mm |

| Application | Hotels/schools/hospitals/factories/workshops/warehouses/outdoor villas, etc |

| Fire rating | B1 & B2 level |

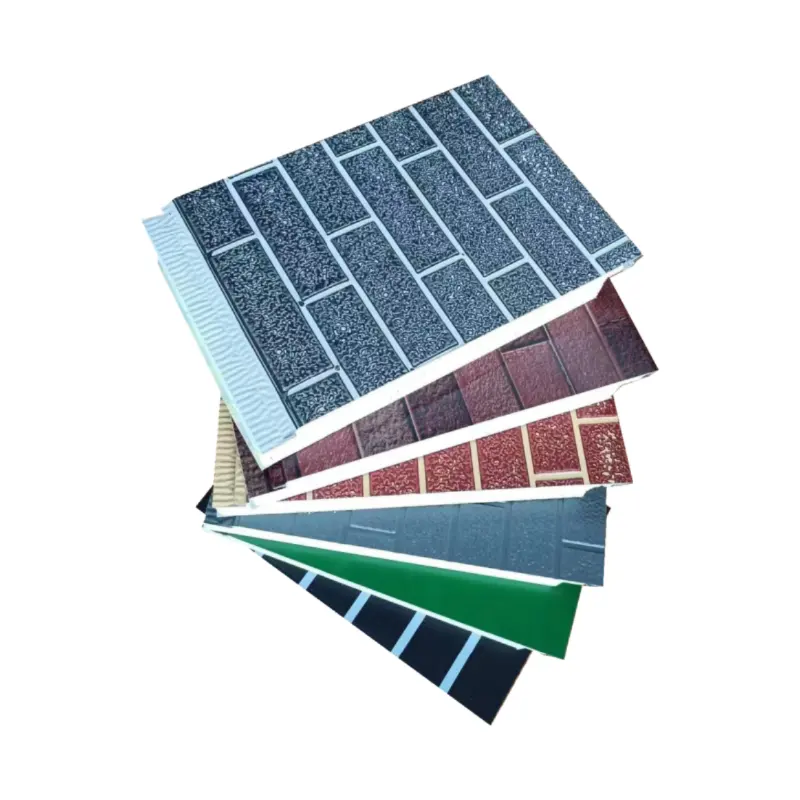

3 layers:

· Surface: 0.25 mm Al-zn alloy coated steel sheet (Al 55%, Zn 43%)

· Middle: 30-100mm EPS foam

· Back : Aluminium foil thermal layer

· Size: Length (1-11.8m) * Width:383mm * Thickness: 30-100mm

· Density: 18-20kg/m3

Standard size: Can be customized

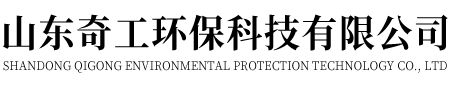

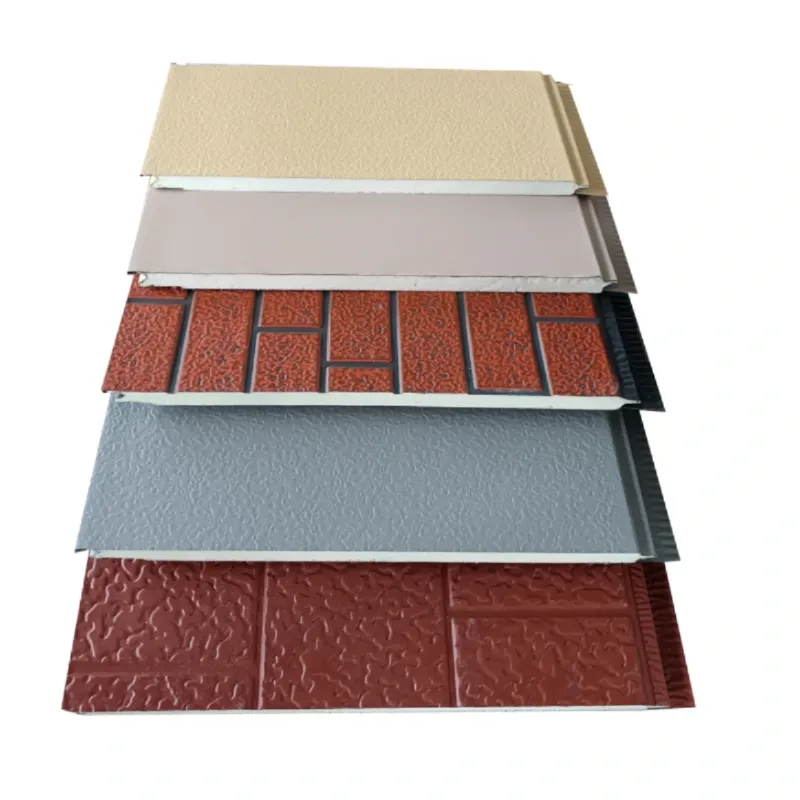

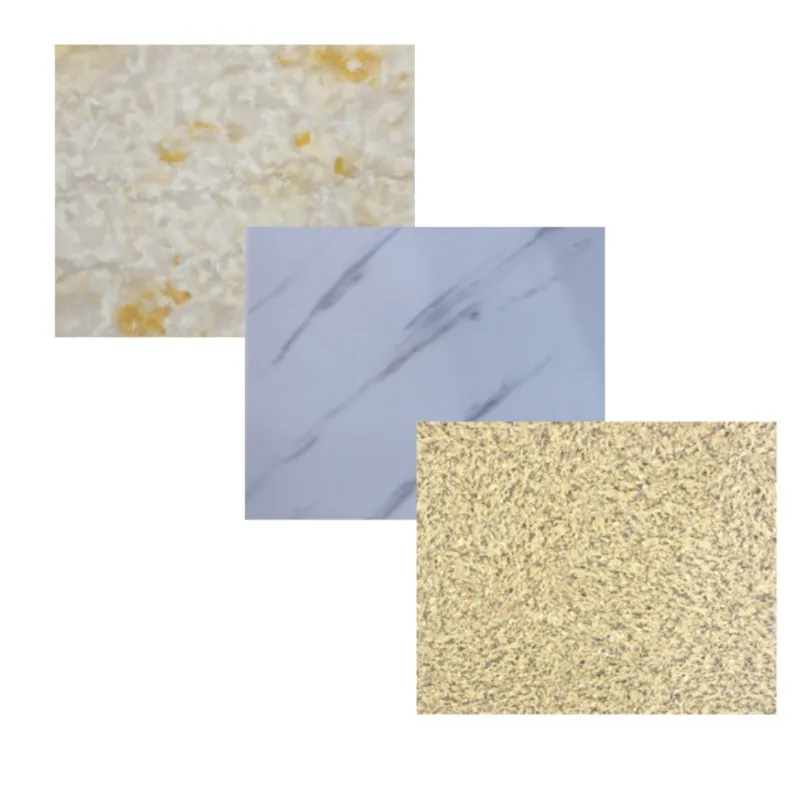

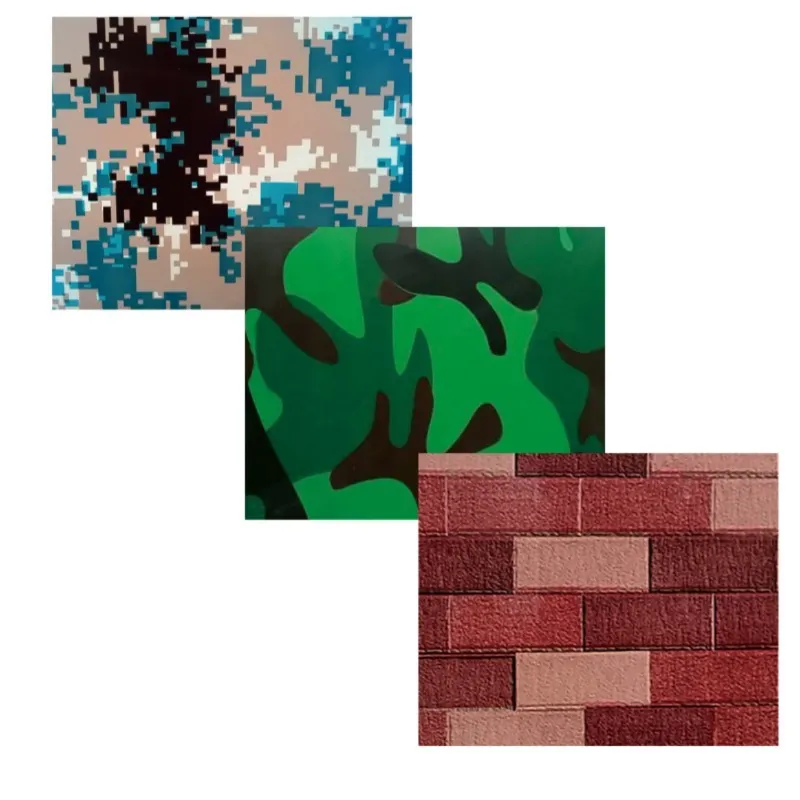

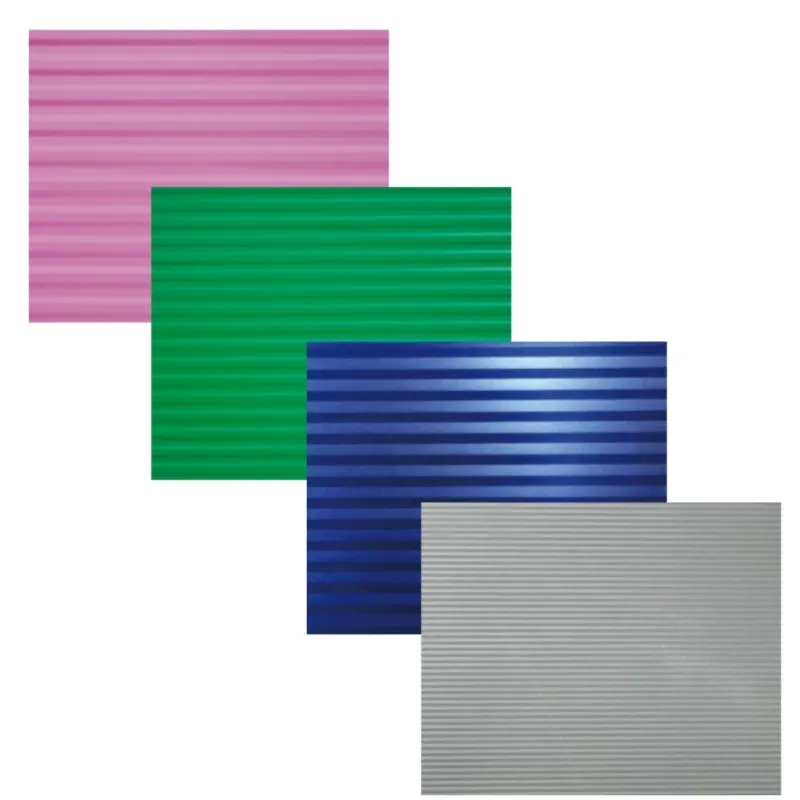

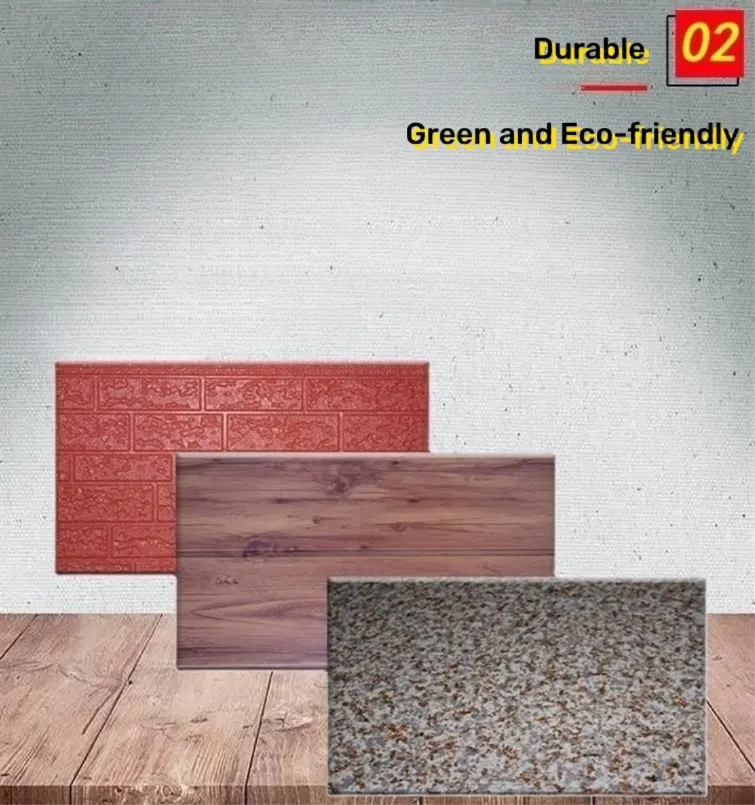

Color and pattern introduction:

There are more than 100 of patterns of SDQIGONG metal sidings. The fantastic decoration effect highlights the grade of buildings. The simple and flexible disassembly and assembly of these metal sidings make the replacement of the design of walls easy.Metal sidings are not only suitable for the thermal insulation decoration of the exterior walls of new brick-concrete structures, frame structures, steel structures, and light-weight houses, but also for the energy-saving renovation of existing buildings, as well as interior and exterior decoration.

As shown in the figure(Note: Because of the colors, patterns can not be shown one by one, the specific message consultation, we will reply you the first time, and all the colors and patterns will be sent to you by email)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

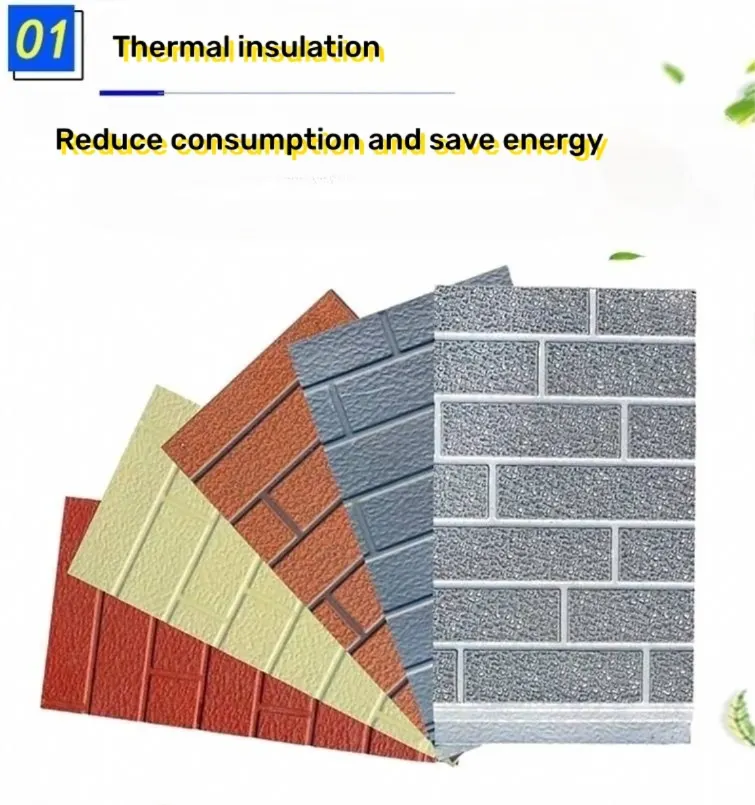

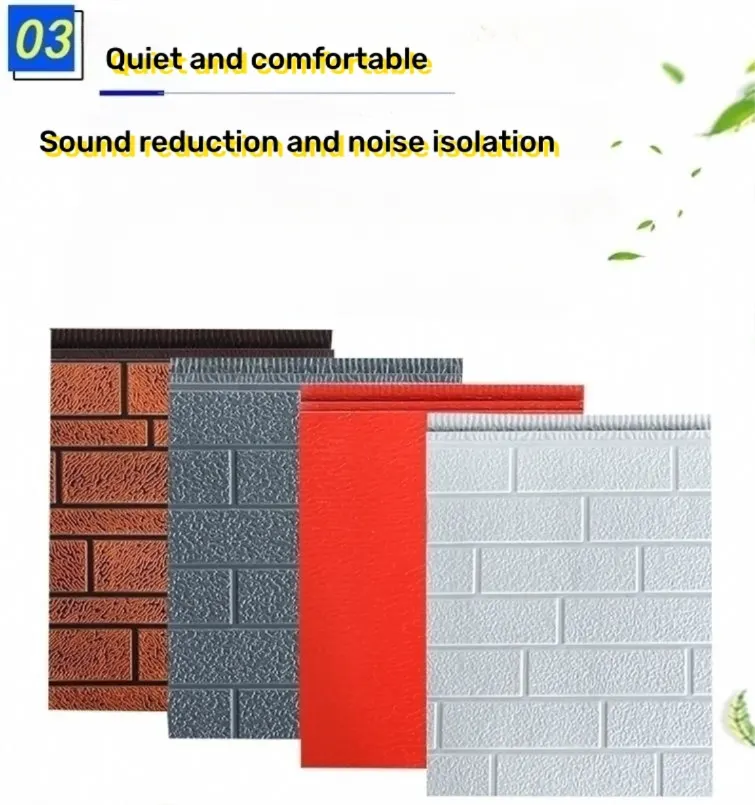

PRODUCT PERFORMANCE:

1. Low engineering cost:

The cost of the sheet metal project is about one-third of the cost of the aluminum-plastic panel curtain wall project, and the decorative effect is very good.

2、Light weight:

The weight is extremely light, convenient to transport and easy to install.

3、Fast construction:

The construction speed is more than double the construction speed of similar materials.

4、Long service life:

15 years without fading, plate life is more than 50 years;

5、Thermal insulation, sound insulation and noise reduction:

Equivalent to the thermal insulation effect of 5cm thick polystyrene board

6、Rich colors and patterns:

Any combination: brick, stone, marble, bark, smear, cultural stone, wood etc.

7、Wide range of applications:

Renovation of old buildings, indoor and outdoor wall decoration, various new buildings, movable rooms, villa,sentry boxes, container houses ,environmentally friendly toilets, modular and prefabricated buildings.

|

|

|

Installation process:

Tools/Materials: Electric drill, expansion screw, self-tapping screw, metal carved plate

1. First place the metal carved board on the wall, power on the hand electric drill, and then use the electric drill to punch holes on the wall at the link of the metal carved board.

2. Then install expansion screws to the holes and fix them with self-tapping screws.

3. Finally, another board is placed above the fixed metal carving board, and the groove of another board is inserted into the slot of the fixed metal carving board. Then repeat the above operation.

4. After the installation, the exterior wall decoration is beautiful, heat preservation and heat insulation, fireproof,moisture-proof and sound insulation.

Matters needing attention:

Make wall level before installation.

When installing metal carving board also want to find level

|

FAQ:

1.You are manufacture factory or trading company?

We are manufacturer factory. You are welcomed to visit us at any time.

2.How about your quality control?

Our products have passed CE.

3.Can you offer design service?

Yes,we have an engineer team and can design for you according to your requirements.Architectural drawing,structure diagram,processing detail drawing and installation drawing will be made and let you confirm in different time of the project.

4.What's the delivery time?

The delivery time depends on the size and quantity of building.Generally within 30 days after receiving the payment.And partial shipment is allowed for big order.

5.Do you offer service for installation?

We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step.

6.What's the payment term?

30% deposit and 70% balance before shipment. L/C is OK .

7.How to get a quote from you?

You can contact us by email, phone, Alibaba TM, WhatsApp and so on 24*7 and you will get reply within anytime.

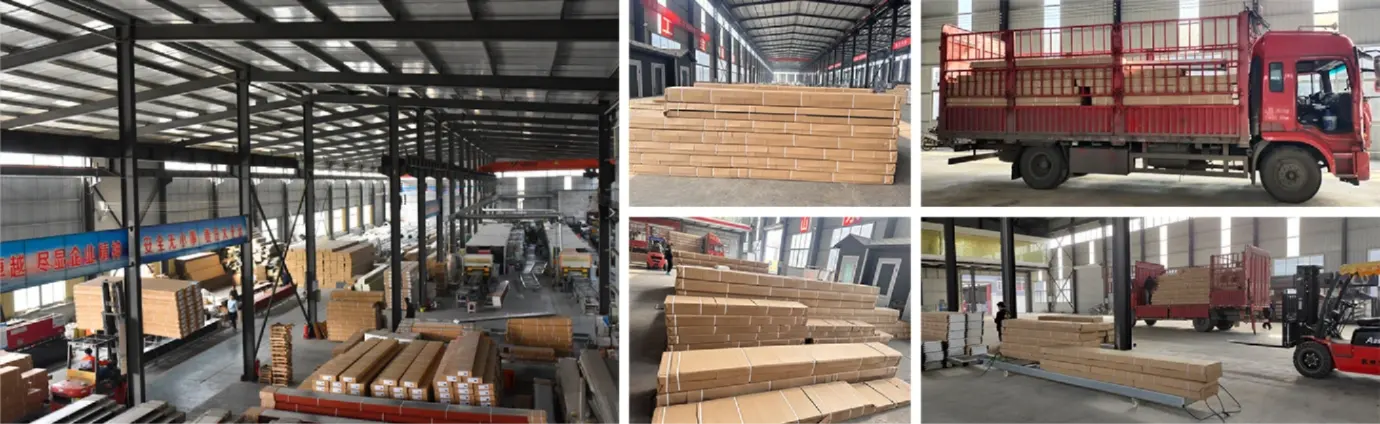

Company Profile

After years of efforts, our products of Shandong Qigong Environmental Protection Technology Co., Ltd have been sold to all provinces, cities and regions of China. In recent years, our products of Shandong Qigong Environmental Protection Technology Co., Ltd have been exported to Korea, Malaysia, Africa, Russia, Australia, the Middle East and other countries and regions. We have more than 10 sets of advanced CNC equipment which to make the wall panels .Automatic production makes the product quality stability, high production efficiency. Different patterns and colors to meet the different needs of customers. Excellent product quality has won the recognition of customers at home and abroad.

Packaging and shipping

Packing:Carton packaging + Packaging belt

(1) Board cabinet size: It is generally required to be 5.8m for 20 foot cabinet, According to the needs of customers, the total length of 40 foot cabinet is less than 11.8 meters (2) Loading information: The size and specification of the 20 foot small cabinet is about 5.898 × 2.352 × 2.385m, and the assembly level is about 1300(excluding spare parts space) 40 large cabinet (high cabinet): 12.032 × 2.352 × 2.69M, about 3300 flat (excluding spare parts space)

Application fields:

light steel villas, activity room sentry boxes, steel structure workshops, green wooden houses, container houses, environmental protection toilets, substation rooms, old building renovation, interior decoration, etc

More products

Message

Contact us

Whatspp:+86-15634809468

E-mail:bob@qigonghb.com

ADD:No. 98, Environmental Protection Technology Industrial Park, Diaozhen Street, Zhangqiu District, Jinan City, Shandong Province

Free solutions for you